About the Department

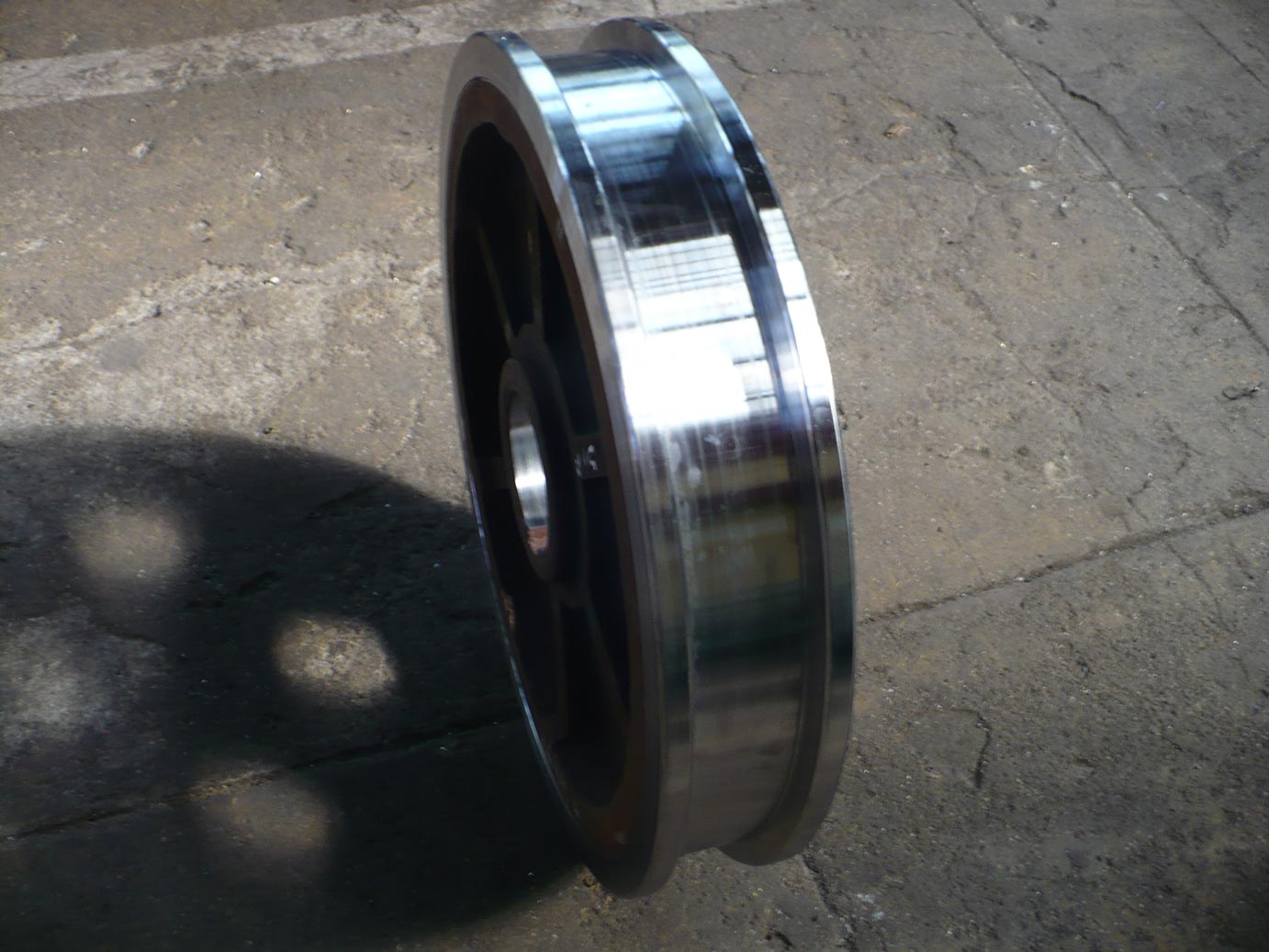

The Appliances Regeneration and Manufacturing Department of LOGIS was created on the basis of Częstochowa Steelworks Department which is specialised in manufacturing new machinery components and their regeneration using weld surfacing performed in the Steel Plant, the Plant Mill, the Tube Rolling Plant and the Coking Plant.

We started to implement very innovative weld surfacing technologies in Częstochowa in 1990 on the base of welding devices of ESAB Swedish company and trainings for employees in Sweden and France.

The most innovative research in Poland was carried out in 1992 in Częstochowa Steelworks causing implementing weld surfacing of rollers of the Continuous Caster in the local plant of VAI company from Austria – the worldwide leader in designing and producing the most innovative steel casting system used until now.

On the base of padding welds, fulfilling roles of plated objects of hardness higher than 42HRC and resistant to abrasion and chemical agents, the technologies of regeneration and production of plungers and cylinders were subsequently implemented what increased the durability of the mentioned parts.

Over the period 1999-2006, the Department was the subsidiary of the Steelworks named ADMET Sp. z o.o. which, additionally, provided services of anticorrosion coatings. At that time the employees gained experience on projects performed for clients all over Poland and during performing services as a basic services provider for Częstochowa Steelworks.

Over the period 2007-2013, the Department existed within the structures of the Processing and Regeneration Plant of ISD, Ukrainian company, at the same time expanding in producing new components and devices using precise machining.

The technologies implemented from the 90’s are nowadays used by the Appliances Regeneration and Manufacturing Department of LOGIS Company in Częstochowa by using welding materials from international producers of flux-cored wires and solid welding wires accordingly with welding methods: SAW, Open-arc, MIG/MAG, TIG and MMA covered electrode.

Our company continues the best tradition with the involvement of experienced, high qualified personnel that has been gaining the professional skills since the 90’s.

Technical parameters of used welds, our close cooperation with foreign consultants of the companies: COREWIRE, SOUDOKAY, CORODUR and scientists from many Universities of Technology in Poland guarantee that out regenerated and produced parts meet requirements of our clients and provide failure-free operation of our products supported by laboratory analyses, approvals of the Technical Supervision Office and warranties.